In order to guarantee the stability of a wind turbine a pile or flat foundation is used, depending on the consistency of the underlying ground.

The tower construction doesn’t just carry the weight of the nacelle and the rotor blades, but must also absorb the huge static loads caused by the varying power of the wind. Generally, a tubular construction of concrete or steel is used. An alternative to this is the lattice tower form.

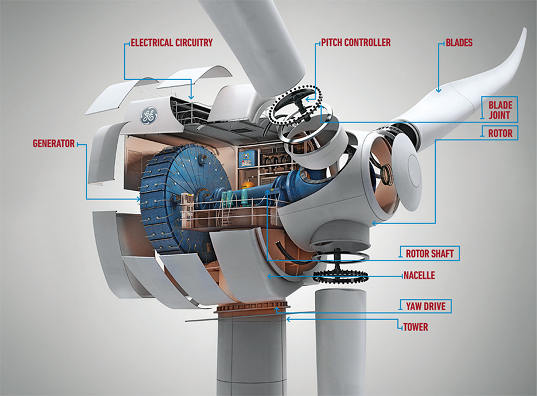

2. Rotor and rotor blades

The rotor is the component which, with the help of the rotor blades, converts the energy in the wind into rotary mechanical movement.Currently, the three-blade, horizontal axis rotor dominates. The rotor blades are mainly made of glass-fibre or carbon-fibre reinforced plastics (GRP, CFRP). The blade profile is similar to that of an aeroplane wing. They use the same principle of lift: on the lower side of the wing the passing air generates higher pressure, while the upper side generates a pull. These forces cause the rotor to move forwards, i.e. to rotate.

3. Nacelle with drive train

The nacelle holds all the turbine machinery. Because it must be able to rotate to follow the wind direction, it is connected to the tower via bearings. The build-up of the nacelle shows how the manufacturer has decided to position the drive train components (rotor shaft with bearings, transmission, generator, coupling and brake) aa) Gearbox

The gearbox converts the rotor motion of 18-50 rpm into the approx. 1,500 rpm which the generator requires.The gearbox thus takes on the task of matching the rotation speeds of the slow-moving rotor and the fast-moving generator, and generally has several steps to cover for various wind conditions.

If a specially developed multi-pole ring generator is used, the gearbox is no longer required (best-known manufacturer of direct drive turbines: ENERCON).

b) Generator

For high power wind turbines, doubly-fed asynchronous generators are most frequently used. Here, the operating rotation speed can be varied somewhat, unlike when using conventional asynchronous generators. Another concept uses synchronous generators. A grid connection of synchronous generators is only possible via transformers, due to the fixed rotation behaviour. The disadvantage of requiring complicated control systems is countered by the overall efficiency and better grid compatibility.bove this machine bearing.

c) Coupling and brake

Because of the enormous torque, the coupling between the main shaft and the transmission is a rigid one. The type of brake depends on the control mechanism for the blades.4. Electronic equipment

The electronic equipment of a wind turbine is composed of the generator (see above), the system for the grid infeed of the electricity, and various sensors.The sensors for measuring temperature, wind direction, wind speed and many other things can be found in and around the nacelle, and assist in turbine control and monitoring (see chapter “Operation and maintenance”).

No comments:

Post a Comment